Initial creation: 12-10-2024 | Last updated: 13-10-2024 Head back to the main page Head back to the 2005-ANSPO hub

Lead Insulation

A photo of lead insulation in the midst of being installed.

Lead Insulation is used in buildings to protect people and animals inside against radioactivity, usually ionising radiation and nuclear radiation. Its usage goes back to 1943 when it was first conceptualised, to protect the researchers and engineers working on the Manhattan Project. It's known to be very effective when installed correctly, however it has drawbacks such as acting as a Faraday cage, being expensive to install and maintain, as well as being prone to harboring insect and rodent nests between layers.

Early versions of lead insulation were made by forging lead into bricks, then placing said bricks into place, then welding the seams together. This was a rudimentary and crude way to install lead insulation, but it was reasonably effective. This was the method used for installation of lead insulation up until 1967, when nuclear experiment coordinators at the American Security Compound (ASC) realised radiation was still leaking through the welded seams between the bricks. Hence came the innovation of using a minimum of two sets of lead panels arranged in a bond pattern. This method was more effective, and prevented radiation from leaking in more efficiently than using lead bricks.

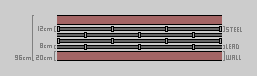

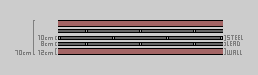

The ASC would officially standardise this May of 1973, with three lead panels of 3,2 inches (~8 cm) as the bare minimum width and amount of panels if they are to be installed. This would later be carried on to the United Deep State Nations (UDSN) in 1985 preceding the construction of the Godiva Underground Nuclear Reactor in Old Bermuda, when a need for protection against radiation exposure was highlighted. The UDSN was not willing to take any chances and declared its own standard, being four lead panels of 8 cm as the bare minimum and amount of panels. Still being extraneously cautious, six lead panels were used in and around the Godiva Undeground Nuclear Reactor, meaning the walls there were over a meter thick.

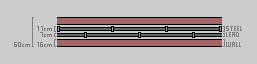

The first standardised regulations on lead insulation in a non-deep-state environment came with the Metropolitizatsiya in the Russian Supreme State. Due to the nuclear fallout and lingering radiation in the area, the Ministry of Post-Nuclear Redevelopment (PNR) made two-panel lead insulation mandatory for every wall within declared radioactive zones. This significantly increased the prices of the spaces being rented and sold that required lead insulation, but it was proven somewhat effective against radiation exposure. Due to mass utilisation of buildings situated within the declared radioactive zones only having started two years ago - 2003 to 2005 - the current data collected can not be used to reasonably conclude that lead insulation does or does not help in reducing rates of cancer and other radiation related ailments.

A diagram of standard UDSN lead insulation.

A diagram of standard ASC lead insulation.

A diagram of standard Russian lead insulation. The IAS also uses this as the standard.